THERMAL OIL SAMPLING

sample at room temperature

does not expose to burn

safe for handling

Safe sampling at a thermal oil plant involves manually sealing the sample directly from the system through which the hot oil is flowing and then cooling it to room temperature. The cooled material ready for testing is safely poured into a transport container, without exposing the operator to the hot oil and preventing potential burns, and then sent for analysis. The entire process is carried out with full implementation of health and safety requirements.

A major advantage is that the thermal oil sample is taken directly from the installation and cooled without contact with air, eliminating the formation of additional oxidation products in the sample as it is taken. As a result, the thermal oil sample more accurately reflects the state of the existing plant's thermal oil charge.

DEAERATOR FOR THERMAL OIL PLANT

We offer a comprehensive service for the selection, manufacture and installation of a deaerator for thermal oil, which is designed to remove the gas fraction (air) from the oil.

The deaerator also removes gas dissolved in the oil.

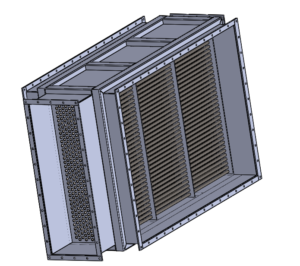

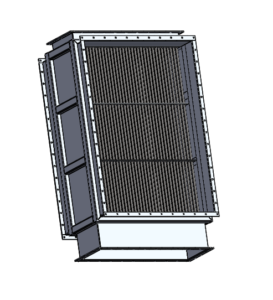

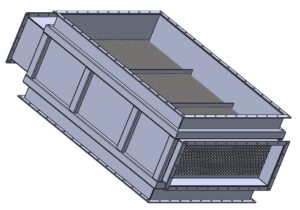

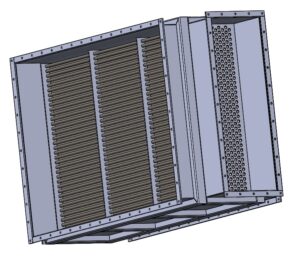

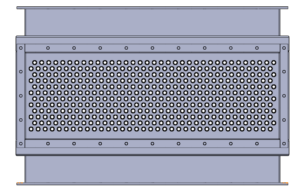

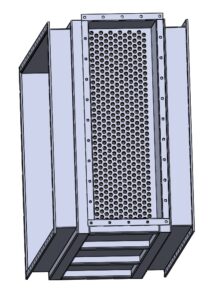

HEAT EXCHANGER FOR NON-STANDARD TECHNICAL TASKS

We specialize in the design/selection and manufacture of unit heat exchangers with various non-standard technical conditions. For exchangers depending on the customer's needs, we offer:

- selection of economizer parameters,

- thermal calculations,

- optimization of exchanger size,

- technological and detailed design

- execution,

- delivery,

- installation and commissioning.

Examples of realizations:

STAINLESS STEEL ECONOMIZER

Due to the design of the stainless steel exchanger, such as 1.4301, it is mainly used in the food industry. The economizer recovers heat from the flue gas and heats the air, which is directed directly to production, such as drying. Flue gas temperature 300°C.

STAINLESS STEEL SHELL AND TUBE EXCHANGER THERMAL OIL / COOKING OIL

Exchanger used in the food industry mainly in frying systems. Its purpose is to prepare the right temperature of oil for frying. The heat carrier in this exchanger is thermal oil. Operating temperature of 300°C.

THERMAL OIL / AIR EXCHANGER

Heater type exchanger, which is used to generate hot air for technological purposes. Operating temperature of 300oC. Often used in the printing industry, drying industry, etc.

This is just a part of our capabilities, if you need a customized design contact us!

EXPANSION TANK OF THE CLOSED SYSTEM

We offer a comprehensive service of selection, fabrication and commissioning for thermal oil expansion tanks for closed system with instrumentation. The tanks are equipped with the following as standard:

• pressure stabilization system

• magnetic level gauge

• minimum oil level indicator

• safety valve

• drain shut-off valve

• vent shut-off valve

• pressure sensor with shut-off valve and accessories

• pressure gauge with shut-off valve and accessories

• thermometer in stainless steel sheath

• insulation: mineral wool in sheet metal sheath

The pressure stabilization system consists of:

- control valves: tank aeration and breathing valves

- necessary shut-off valves and fittings

- supply and control cabinet with pressure regulator

Power and control cabinet equipped with signal strip: minimum level,

measuring actual pressure inside the tank, contact with information about exceeding the maximum

permissible operating pressure - the possibility of linking with the superordinate control system.

From the controller located in the supply and control cabinet, it is possible to set:

- threshold pressure of opening the bleeder valve together with the hysteresis of work

- threshold pressure of opening the tank aeration valve, together with the operation hysteresis

- maximum allowable pressure - for use in the automation of the master control system control system.

control system

Location of tank connection stubs determined individually to the needs of a specific installation.

installation.

The tank is delivered with full as-built documentation: instruction manual, declaration of conformity,

required UDT acceptance, etc.

OPEN SYSTEM EXPANSION TANK

We offer a comprehensive selection, fabrication and commissioning service for open system expansion tanks. Tanks of this type are equipped with a minimum level indicator and the necessary stub pipes and vent piping.

Location of tank connection stubs determined individually to the needs of a specific installation.

installation.

The tank is supplied with full as-built documentation: instruction manual, Declaration of Conformity

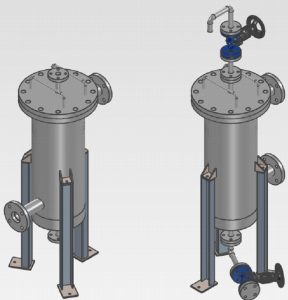

FILTER - MICROFILTRATION AT 300°C

Do you operate on thermal oil? We have developed an innovative filter for microfiltration of thermal oil at high temperatures suitable for installation in a thermal oil plant. You can find details along with a wide range of available solutions HERE.Want to order or have questions? Get in touch with us!

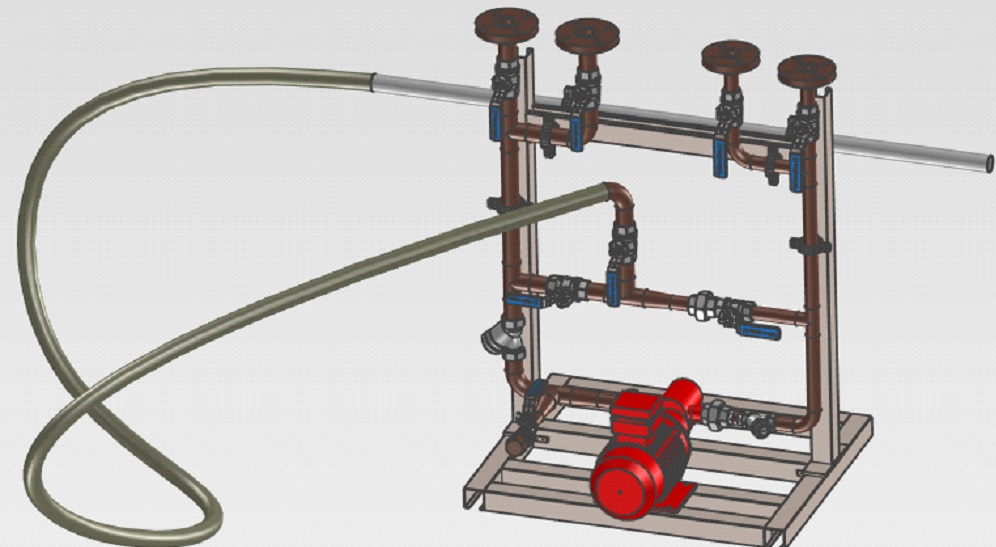

THERMAL OIL FILLING AND DRAINING SYSTEM (UNO - 150)

Need a fast and practical solution for a filling and draining system for thermal oil? We have developed a reliable solution suitable for installation in a thermal oil system. The flexibly attached lance allows convenient filling or draining from the installation.

- Adapted for installation in thermal oil installations;

- Allows thermal oil installations to be filled from drums and from a storage tank;

- Allows emptying the thermal oil system into barrels and into the storage tank;

- Simple and convenient change of flow direction;

- Lance attached by flexible cable allows convenient filling and emptying of drums;

- Ready-made frame allows quick installation.

Click HERE. and check out the details.

THERMAL OIL STORAGE AND DISCHARGE TANK

This type of tank is designed to store thermal oil. It also plays a very important role in emergency and service situations, among other things:

- takes over the charge in the situation of emergency oil discharge, which occurs, for example, when the installation is unsealed;

- discharge of thermal oil through the safety valve;

- overflow of the expansion tank, discharge of oil through the overflow of the expansion tank;

- filling, replacement of thermal oil.

- We offer a comprehensive service of selection, construction and installation of a storage and discharge tank.

- Location of tank connection stubs determined individually to the needs of a specific installation.

- The tank is supplied with full as-built documentation: instruction manual, Declaration of Conformity

HEATING OIL PUMPING SYSTEM

Fuel oil pumping system is designed to supply oil to oil burners from storage tanks.

Typical system equipped with two pumps where one is a hot reserve. This improves the reliability of the installation ensuring uninterrupted operation of the system.

Our systems can work with one or more storage tanks, depending on your needs. If there are more tanks there is a possibility of pumping fuel oil between tanks.

We provide:

- an installation design optimized for your specific needs

- implementation

- installation or installation guidelines

- commissioning, operating instructions

- warranties

- employee training

An example of the system we have implemented is shown in the photo below.

Need a customized look at a solution? Get in touch with us!